Application of Hyperspectral Imaging in Industrial Food Packaging

Hyperspectral imaging (HSI) captures information that is not available to the human eye. In addition, it can provide spatial information, as well as spectral information for each pixel in the image.

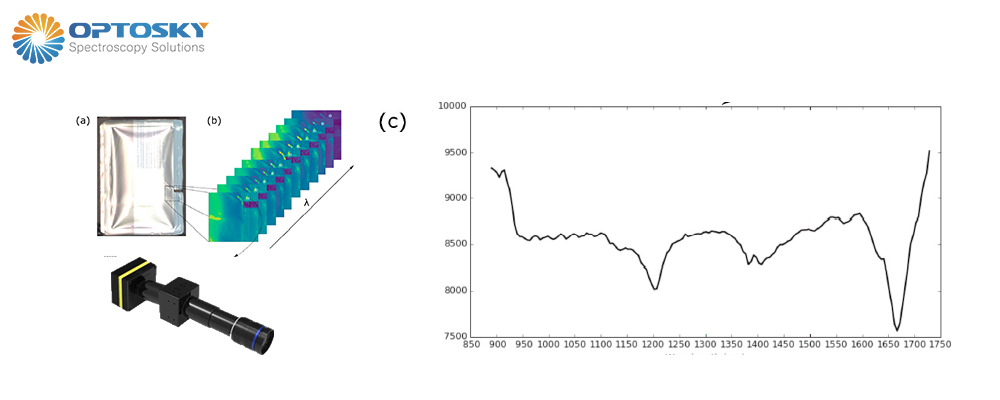

Food, just as many other packaged products, requires high quality sealed packaging to meet modern safety and quality standards. Seal integrity and food contamination during processing and packaging are major causes of food waste in manufacturing, distribution, retail and home environments. Traditionally, we use the visual system to inspect packaging, however, due to the transparency of the material, this method is unable to identify some specific sealing problems, one of the most important problems is the lack of objectivity due to observation fatigue. In addition, although RGB cameras can quickly identify features such as color, shape, texture and size, chemical composition given by spectral analysis cannot be obtained due to limited spectral information. Many systems have been developed to classify, control, or identify seal anomalies in the manufacturing product chain. Hyperspectral imaging (HSI) captures information that is not available to the human eye. In addition, it can provide spatial information, as well as spectral information for each pixel in the image.

for heat-sealed food trays to demonstrate the feasibility of online classification using hyperspectral imaging systems for real-time food packaging control. They used a hyperspectral camera to capture individual food trays and feed it to A CNN classifier to detect defective food trays contaminated with objects. The system is capable of detecting up to 11 different contaminated products (plastics, rubber, etc.). If a defective pallet is present, it is discarded from the automatic production line. They also build specific databases with different defects and normal conditions. Various techniques are proposed for CNN architecture and its training.

Comments: 0

No comments